Build Diary entries for February 2017

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Engineering update 2nd Feb 2017 |

| 02/02/2017 |

| |

|

| |

A very busy week as the above photos shows.

The assembly on the left is the smokebox saddle which incorporates the exhaust steam spider. The exhaust steam spider was cast using the new sand printing technology to create the mould. The vertical stretcher on the right is a combined frame stretcher and boiler carrier.

The combined frame stretcher with spring hangers are to be machined shortly. This is another big step forward as these castings are extremely complex and, due to their size, finding a company that could machine them caused the engineering team as much of a headache as getting them cast! CTL Seal has stepped up to the challenge.

Appeals, there are still a few 'bag of bolts' remaining should you wish to sponsor these crucial parts. The Extra Push appeal is also progressing well and will fund the additional work to include the frame extension and drag box in the initial assembly. There have been a few questions as to why the extensions are now being included, quite simply this will save more work (at a higher price) to complete later rather than now and will produce a complete frame assembly.

As always, the speed of the build is dependent on funds, believe me, the engineering team can spend it quicker than the rest of us can raise it! |

| |

|

| Engineering Update |

| 03/02/2017 |

| |

Yes things are moving that quick!

Quick on the heals of yesterdays update comes some additional news from Engineering Committee member Graham Ashton:

Also ordered - machining of all 3 cast steel frame stretchers and 4 of the fabricated horizontal frame stretchers all to be done by CTL Seal. |

| |

|

| Engineering News - 7th February 2017 (1) |

| 07/02/2017 |

| |

|

| |

The above photo (taken in low light unfortunately) shows five pressed frame stretchers, a combined cast stretcher with spring hangars and the stretcher with brake cylinder support being loaded ready to go to CTL Seal for machining. The remaining two combined stretchers have also been delivered for machining.

Frame stretcher 21990, aka the bread basket tray is due back from machining imminently. |

| |

|

| Engineering News - 7th February 2017 (2) |

| 07/02/2017 |

| |

|

| |

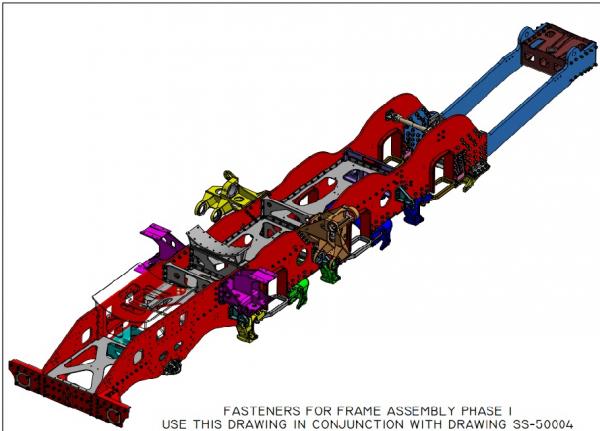

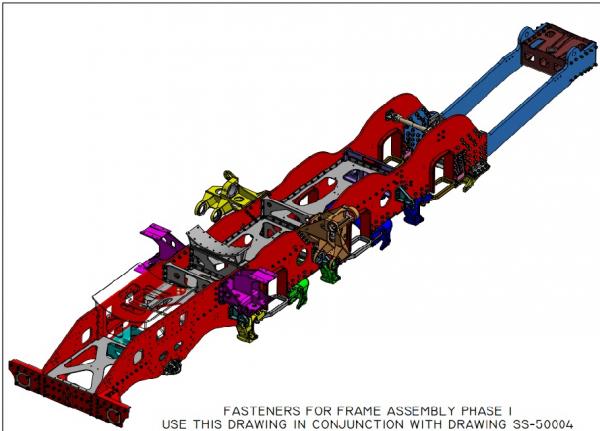

The CAD drawing above shows how the assembly will look when complete. The rear frame extensions, drag box and the assembly for the truck pivot can clearly be seen in the top right. Believe it or not everything seen here is now in stock, either machined or about to be machined! |

| |

|

| News Update - January 19th 2017 |

| 19/02/2017 |

| |

|

| |

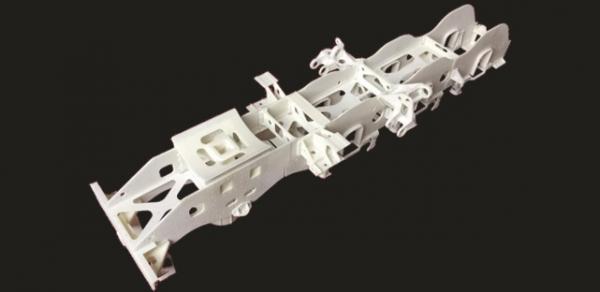

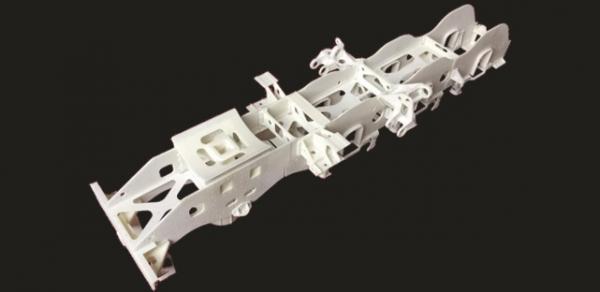

It's been a busy start to the year. CTL Seal are currently profiling the plates for the dragbox assembly. We are also awaiting quotes for machining various components ahead of the frame assembly commencing.

The bolting arrangement is being completed by the Engineering team and the necessary bolting schedule drawings drawn up. Once this has been approved the bolts can then be manufactured.

The above photo shows the updated 3D printed model of the frames and components that we have in stock minus the rear frame extensions and dragbox assembly. Note the addition of the slide bar brackets and motion brackets. |

| |

|

| Engineering update - 19th February 2017 (1) |

| 19/02/2017 |

| |

|

| |

The combined stretchers and pressed stretchers are being prepared for machining at CTL Seal. The photos show one of the combined frame stretchers being measured using the latest measuring equipment. |

| |

|

| Engineering update - 19th February 2017 (2) |

| 19/02/2017 |

| |

|

| |

Another view of the combined frame stretchers. The stretchers are upside down. |

| |

|