Build Diary entries for May 2019

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Previous Month | Return to 2019 | Next Month |

| Trial Fit of Frame Components | |

| 01/05/2019 | |

|

|

| CTL Seal are trial fitting the vertical frame stretchers and the smokebox saddle to the main frame plates to ensure that all of the joining holes line up correctly. All holes have been deliberately drilled 1/16" undersize to allow for slight misalignments. The initial assembly will take place with undersize bolts. This will allow for the frames to be accurately aligned before the final bolts holes are drilled and reamed for fitted bolts. | |

| HENGIST frame update. | |

| 09/05/2019 | |

| The main internal frame components have now been bolted in place. The frames will next be turned upright and lowered over the lower cast frame stretchers which are in the foreground of the photo. | |

| Frame Assembly Continues (1) | |

| 10/05/2019 | |

|

|

| Here are the first photos of the main frame plates assembled onto the frame stretcher. The view is from the rear of the frames, | |

| Frame Assembly Continues (2) | |

| 10/05/2019 | |

|

|

| Here is a view from the rear of the frame assembly. The thiinner lower bar is a temporary fitment to hold the frame plates correctly. | |

| Frame Assembly Continues (3) | |

| 10/05/2019 | |

|

|

| A final view from the front of the frames. At this stage only temporary, undersize bolts have been fitted. Once all of the inter frame components have been fitted, we will then go through an alignment phase to ensure the frame plates are parallel to each other and are in line. | |

| HENGIST frame update. | |

| 13/05/2019 | |

| Today's visit to CTL Seal for our usual weekly working party enabled us to get this latest view. The frames have now been bolted to the three lower cast stretchers and have most of the internal items in place. The whole structure has been mounted on adjustable frame stands, four are situated inside the frames between the lower stretchers with a further two supporting the front of the frame assembly. | |

| Frames in Perspective | |

| 20/05/2019 | |

|

|

| When you compare the frames a couple of people alongside, the size of the the assembly is very apparent. We can only fit the frame extension plates to the left hand side after the hornguides have been machined. Otherwise we can't get the assembly on the machining station. Tom Wade from CTL Seal and Geoff Turner from SSLC discuss the next jobs. The vertical stretchers were fitted to the frame plates with the assembly on its side. Follow the link to this video to see how the assembly was turned through 90 degrees. |

|

| Pattern Orders Placed | |

| 28/05/2019 | |

|

|

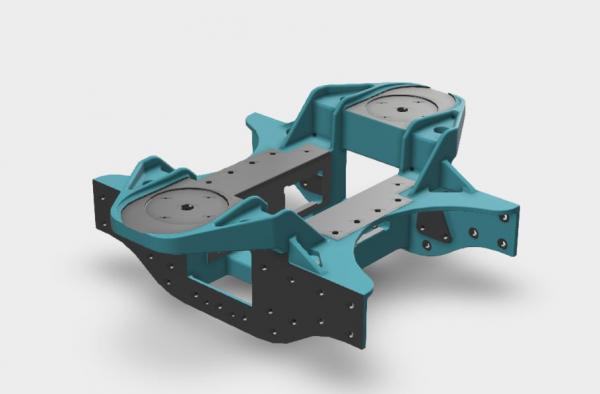

| With frame assembly now well under way, we are starting early work on the next major construction phase which will be the bogie. We've placed orders for the casting patterns for the central bogie stretcher casting (CAD model image above), the centre slide and the axle box guides. 8 axle box guides will be required, the pattern is common to all of them. A donor has now sponsored the casting of the stretcher and the centre slide. If you would like to sponsor the axle box guides or other items on the bogie please have a look at the bogie appeal page. We have a number of bogie parts in stock and will be placing an order for the drilling of the side frames soon - the frames are in stock. |

|