Build Diary entries for August 2019

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Bogie Pivot Pin Collar and Ring |

| 05/08/2019 |

| |

|

| |

There's not a lot of progress to report on this week as we wait for a couple of frame parts to be returned from machining. On the inspection table today was the bogie pivot collar (in 2 halves) and the locking ring, kindly sponsored by a member. The bogie pivot is attatched to the bogie frame stretcher. When the bogie is fitted, the pin engages with the centre slide (see Construction > Build > Bogie) on the bogie. The 2 halves of the pivot collar are fitted below the centre slide and engage with a slot on the pivot pin. With the collar fully engaged, the locking ring slips over the top of the collar and is locked in position by the bolt. This securing the bogie to the main frames. |

| |

|

| Buffer Beam Angle |

| 05/08/2019 |

| |

|

| |

Prior to establishing our base at CTL Seal in Sheffield, our parts lived in various locations up and down the country. Fortunately, we only managed to lose one item and this was the left hand buffer beam angle. With thanks to Alphaweld, a fabrication company based at Calver in the Hope Valley, Derbyshire, a new angle has been manufactured. The right hand angle can be seen in the right of the photo. The new angle will be receiving a coat of paint shortly. |

| |

|

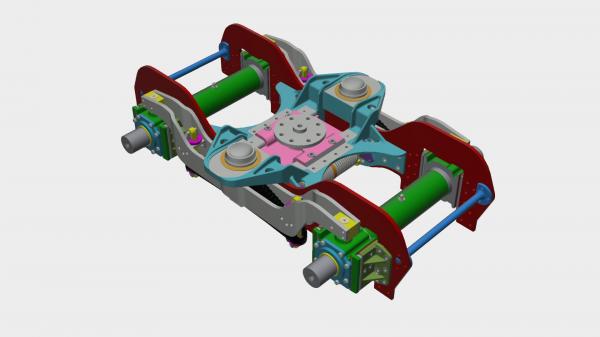

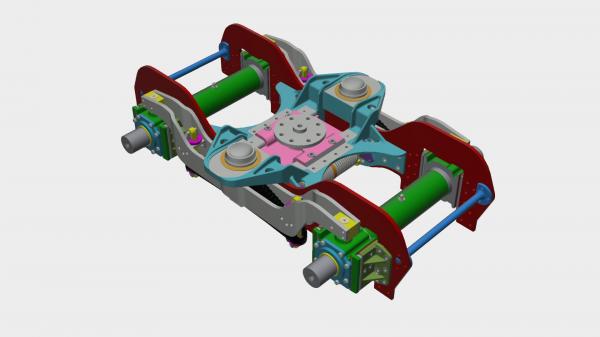

| Bogie Assembly CAD Model |

| 19/08/2019 |

| |

|

| |

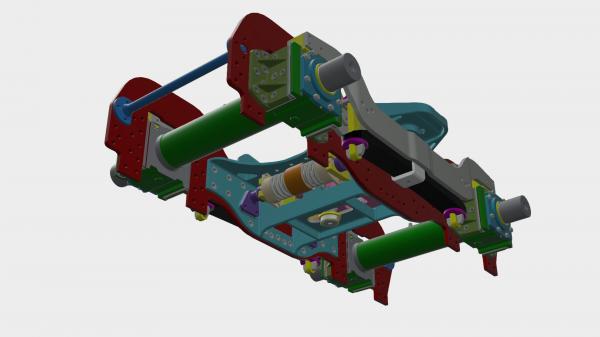

Keith, our CAD modeller, has been busy building the 3D model of the bogie assembly. This is a a valuable exercise as it can be very difficult to read the dimensions off the original British Railways drawings. The 3D CAD model allows us to ensure that all components will fit correctly. Keith still has to model the frame keeps, AWS receiver stay and lifeguards. The bogie, like the frames, will be assembled with fitted bolts. Keith's last job will be to add all of the bolts and ensure that none of the bolts foul other components. |

| |

|

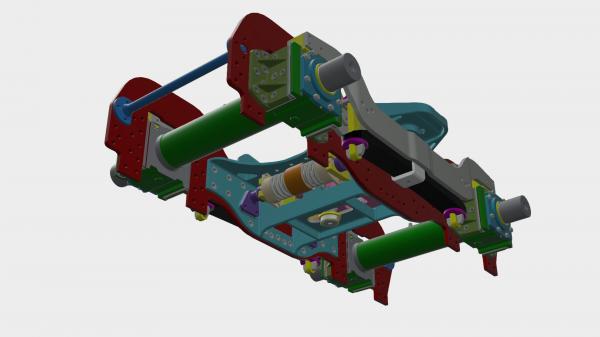

| Bogie Assembly CAD Model (2) |

| 19/08/2019 |

| |

|

| |

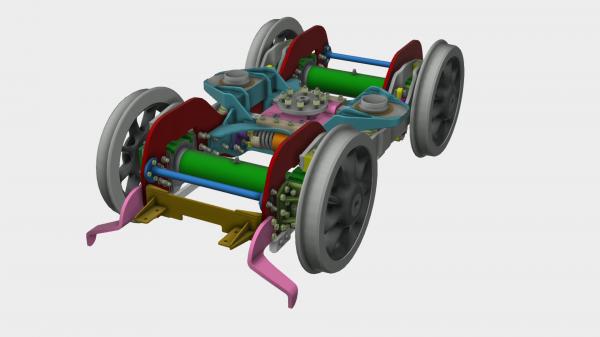

Here is the underside of the bogie. Keith says that each leaf of the leaf spring had to be modelled separately and that he couldn't find a method to automate it - a slow process. At the moment we are still exploring options for the side control spring. We have not been able to find a manufacturer who can supply the original rectangular section springs. The solution in the image uses a nested inner/outer pair of round coil springs to provide the same characteristics of the original. The spring guides at each end of the springs have enclosures round the base of the springs to ensure they are located correctly. |

| |

|

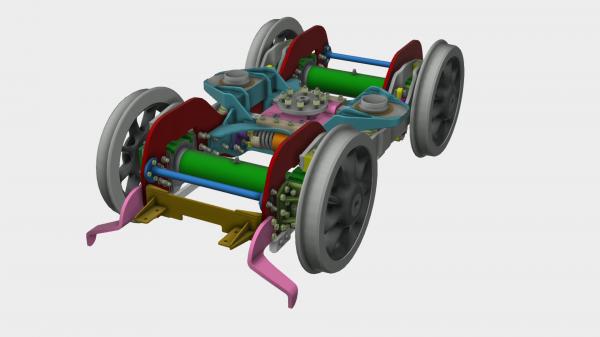

| Bogie CAD Model Complete |

| 28/08/2019 |

| |

|

| |

Keith has now finished the 3D CAD model of the bogie. This give us the reassurance that we've read all of the dimensions from the drawings. The reproduction quality of the drawings can be poor and it can be difficult to determine a dimension. We've been analysing the model in 3D and have checked that we have no clearance problems. Now we need to built it - if you can help, please see the appeals page! |

| |

|