Build Diary entries for March 2020

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Previous Month | Return to 2020 | Next Month |

| Machining the Stretchers | |

| 02/03/2020 | |

|

|

| Over the winter we've been doing a lot of checking of the frame assembly before we commit ourselves to hornguide and frame keep machining. Our aim in this project is to make sure that a job is right and not accept flaws. It's been accepted that the frame plates are not sitting tightly on the cast steel stretchers and that there are high points that need to be addressed. Therefore the stretchers are back in the machine shop. We have agreed with CTL Seal that we need to procure a cutter head that will allow us to machine the key horizontal face (as highlighted with blue) in a single pass. The cutter was ordered from Glasgow today and should be delivered tomorrow. Meanwhile we will turn the frame plates assembly over so that we can do a thorough flatness and squareness check on the lower face of the frame plates | |

| Bogie Bolts | |

| 02/03/2020 | |

|

|

| Today the last of the bogie bolt order arrived into stock. As for the main frames, we are using fitted bolts instead of cold rivets. On the left are the countersunk bolts used to secure the bogie frame plates to the central stretcher. We've followed the British Railways drawing in specifying countersunk head bolts in some locations. The main suspension spring cradle (a compensation beam) sits outside of the frame plates and alongside them. As space is very limited, countersunk head rivets were specified in this area. As a light drive only is specified we've added a hex socket so we can make sure that we can tighten up the nut without the bolt spinning. The middle bolt is a heavy drive bolt for the axlebox guides. The right hand bolt is a special bolt for the top 2 bolts on the inner axle box guides where the spring cradle gets close to the bolt heads. Again it reflects the BR drawing style of head. | |

| Stretcher Machining Complete | |

| 09/03/2020 | |

|

|

| Following last week's discussion, all of the 3 cast steel stretchers have now been machined along the face where the frame plates sit on. | |

| Frame Assembly Ready for Inspection | |

| 09/03/2020 | |

|

|

| Meanwhile, the frame assembly has been inverted ready for an inspection. The plan is for CTL Seal inspection to inspect the bottom face (now on the top) for squareness and flatness. If we find an anomaly, then the frames will go for a light machining. The threaded bars at the front are temporary to retain rigidity during transportation. | |

| Bogie Parts (1) | |

| 16/03/2020 | |

|

|

| More bogie parts arrived into stock today. First off is this heavy bit of metal. On the drawing it looks like a small afterthought, in reality this is 7-1/4" high (180mm) and 5" (127mm) internal diameter and its heavy. This is the cast iron bush for the bogie pivot and the 2 set screws that will secure it in place. This will need to be pressed into the centre slide casting which is due from the foundry in a couple of weeks. | |

| Bogie Parts (2) | |

| 16/03/2020 | |

|

|

| The second set of bogie parts are these "V Strips". They are both upside down; their job is to retain the centre slide. The centre slide engages with the bogie pivot but is allowed to move from siste to side while being restrained by the side control springs. The bevel of the V strips is matched by a bevel on the centre slide, thereby the V strips prevent the centre slide from moving upwards while allowing it to move sideways. | |

| Central Bogie Cast Stretcher | |

| 23/03/2020 | |

|

|

| The central cast stretcher for the bogie has been returned from the foundry after some rectification work was completed. In the photo, the stretcher is upside down and the patterns are on the pallet behind. The stretcher is now ready to go for machining. We have already produced a machining drawing and an order has been placed for machining with CTL Seal . |

|

| Bogie Frame Plates | |

| 23/03/2020 | |

|

|

| Bogie parts are coming in thick and fast at the moment! Machining is now complete on the 2 side plates and these will be moving into the assembly area fairly shortly. The top plate has the front on the right, the bottom plate has the front on the left. The difference is the 3 extra holes; originally for the lifeguards at the front of the bogie but later for the Automatic Warning System carrier stay that was added | |

| More Bogie Parts | |

| 23/03/2020 | |

|

|

| Another pair of bogie parts are in the machine shop. This is one of the 2 side control spring beams. As a picture paints a thousand words, the best way to explain these is to look at this page and view the sixth picture down. The beams are the yellow components. The beams slot into the rectangular holes that you can see on the bogie stretcher and the arms engage with the outer ends of the side control springs. As the centre slide tries to move to one side, the beam arms will compress the side control spring, thus providing a resistance to the movement. Machining is not quite complete. | |

| Castings Arrive! | |

| 30/03/2020 | |

|

|

| CTL Seal took delivery of a pallet of castings from South Lincs foundry last week. Although our Monday working groups have been cancelled, Geoff went in to CTL Seal to do a Goods Inwards check so that we can pay the invoice. On the pallet are the bogie centre slide, the bogie axlebox guides, the trailing truck bolsters and the rear driving wheel rear spring hanger. | |

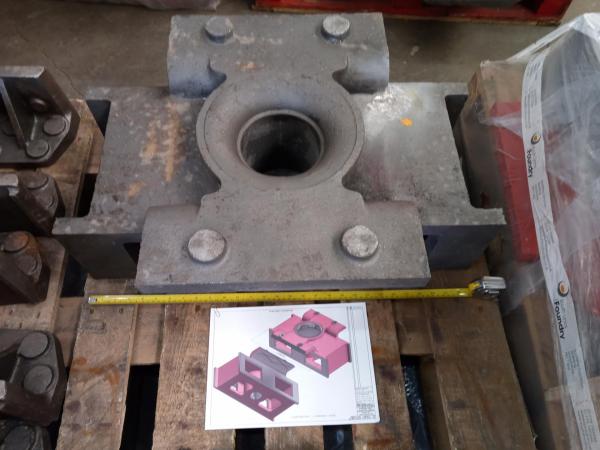

| Bogie Centre Slide | |

| 30/03/2020 | |

|

|

| This is the bogie centre slide. The pivot pin fixed to the locomotive frames engages with the central hole. The centre slide is free to move sideways on the bogie stretcher, controlled by the side control springs. An order has already been placed for the machining of this component. | |

| Bogie Axlebox Guides | |

| 30/03/2020 | |

|

|

| 8 axlebox guides are need for the bogie. For casting, the guides are identical. For machining, the inner axle box guides (looking at the side of the bogie) are different as they need recessed fixing holes for the top 2 bolts/rivets. This avoids fouling the spring cradle. Again, an order has been placed for machining of the guides | |

| Spring Hanger Bracket | |

| 30/03/2020 | |

|

|

| The lot 242 Clans (that were never built) had a revised frame design which they share with 71000 Duke of Gloucester. The rearmost spring hanger bracket is a separate casting; unfortunately the National Railway Museum did not have the drawing for the part. We were able to measure the bracket on 71000 and develop our own drawings - this is the result. | |

| Trailing Truck Bolster | |

| 30/03/2020 | |

|

|

| The final castings to arrive today are a pair of trailing truck bolsters. These are bolted with the domes downwards to the bottom of the hind beam gussets. The weight of the rear of the locomotive is transferred via these bolsters to bolster cups that are free to float on a bearing surface on the trailing truck frame. The bolsters will need to be machined including the holes for oil lubrication. | |