Build Diary entries for September 2020

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Previous Month | Return to 2020 | Next Month |

| Bogie Lubrication Fittings | |

| 05/09/2020 | |

|

|

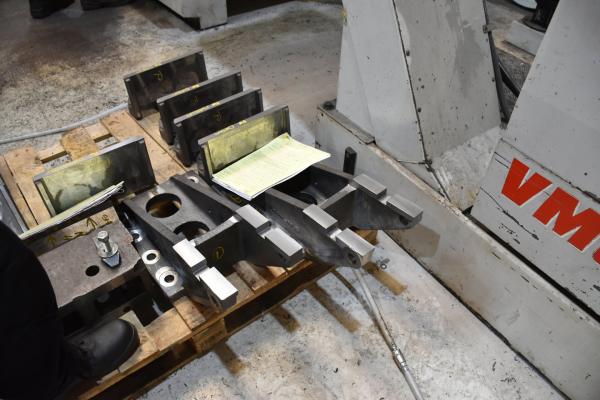

| Not all of our machining takes place at CTL Seal. Ian is one of our members who has a workshop at home. He has very kindly offered to manufacture the various fittings that are need for the bogie lubrication. The centre slide is lubricated by oil. The oilbox is fitted to the frames and the oil travels via 4 flexible pipes to the bogie centre slide. The axlebox and bolster pads are lubricated by grease - although the latter is subject to a lot of discussion! Grease nipples are fitted to a carrier on the ends of the bogie stretcher and fed via pipework to the axklebox guides and the bolster pads. Ian's machine is a Bridgeport turret milling machine and the component is item 8 SL/DE/19799 grease bulkhead fitting,its having the hexagon milled on it. The bulkhead fitting is on the grease nipple carrier; the grease nipple is fitted to the front side and the pipe is connected via a union to the rear. Many thanks to Ian for taking on this work. | |

| Trailing Spring Hanger | |

| 07/09/2020 | |

|

|

| The frames were supposed to moving to the hornguide machining station today. Unfortunately, the machinist who has been briefed for the job was off sick last week so hornguide machining is postponed until next Monday. Meanwhile, on one of the smaller machining stations at CTL Seal is this trailing spring hanger. The hanger comes from the Duke of Gloucester 71000 frame design which was destined for the lot 242 Clans. Unfortunately, we couldn't locate the drawing for this component. Fortunately 71000 was under overhaul so we could measure it and create our own drawing. It is upside down here. The small hole in the vertical section will be filled with a grease nipple and is the lubrication point for the trailing truck pivot. |

|

| Centre Slide Lubrication Bracket | |

| 07/09/2020 | |

|

|

| Over in Ian's workshop are these 2 castings for the bogie centre slide lubrication bracket. This are fixed to the bogie pivot stretcher on the main frames and allow flexible pipes running up from the bogie centre slide to be connected to the fixed pipework on the frames. We had 2 in stock but need 2 more. Ian has got hold of the wooden orange pattern and has made the 2 castings. They will now go onto a machine for finishing | |

| Hornguide Machining - Set up Day (1) | |

| 14/09/2020 | |

|

|

| Today saw the moving of the frames onto the Juaristi machining station at CTL Seal. Setting up the frames on the machine is scheduled for today and overnight. In the morning we are going back for a final check before machining actually starts. The image shows the start of the job as Luke, the machinist at CTL Seal, works out where he will support the frames on the machine bed. | |

| Hornguide Machining - Set up Day (2) | |

| 14/09/2020 | |

|

|

| Later on in the afternoon, Luke had started to set up the many supports to hold the frames securely | |

| Hornguide Machining - Set up Day (3) | |

| 14/09/2020 | |

|

|

| Luke and Tom discuss what to use as a datum point | |

| Pony/Trailing Truck Bolsters | |

| 14/09/2020 | |

|

|

| Meanwhile, the pony/trailing truck bolsters have completed machining and are in the inspection bay. The bolsters bolt to the bottom of the hind beam gussets. They transfer the weight of the rear of the locomotive to the trailing truck.The final job was to machine the oil lubrication grooves. | |

| Hornguide Machining Day 2 | |

| 15/09/2020 | |

|

|

| Geoff and John went in to CTL Seal today for a final check. The set up was very accurate; however they did note a slight sag in the frames measured in tens of thousands of an inch - that was corrected. In the image, Geoff and Luke are discussing the final set up. You can see a short video here of the first metal being cut to set the datums up. Photos by John Hind. | |

| Hornguide Machining Day 6 | |

| 21/09/2020 | |

|

|

| The machining of the inner faces of the hornguides continues at CTL Seal. The photo shows Luke checking the set up with a dial gauge before making the next cut. In this job, you can never do enough checking! You can see a short video of the machining in action by following this link. The cutter is working on the inside face of the trailing hornguide. | |

| Trailing Spring Hangers | |

| 21/09/2020 | |

|

|

| The trailing spring hangers have now completed machining. The design is unique to 71000 Duke of Gloucester and the lot 242 Clans. Unfortunately, the original British Railways drawing did not survice but, fortunately, 71000 did! We were able to measure the spring hangers from 71000 and create our own drawing. The photo also shows the 8 bogie axlebox guides waiting for phase 2 machining. | |

| Casting of Pony Truck Wheels | |

| 25/09/2020 | |

|

|

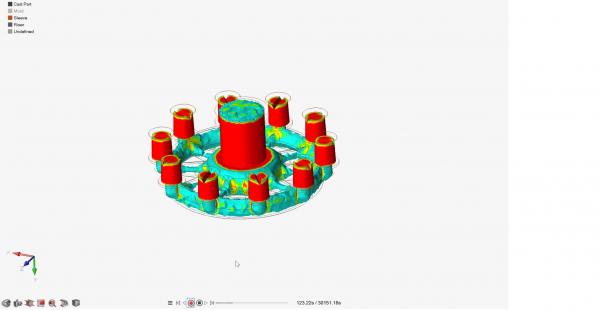

| We've placed an order for the casting of the 2 pony truck wheels - also known as the trailing truck. - with Boro Foundry of Stourbridge. The pattern has been kindly loaned by the Mid Hants Railway. Boro need to work out how to feed in the molten metal and let the air out. So feeder heads are attached to the pattern as you can see in the image, 10 around the outside and a large one in the centre. The image is from simulation software used by Boroand is used to check how the molten metal will solidify. The aim is that the last metal to solidify is in the feeder heads. If you click on this link you can see an animation from the simulation program. The molten metal is red and cools through yellow, green and blue. | |

| Hornguide Machining Day 10 | |

| 28/09/2020 | |

|

|

| The hornguides are now starting to look like the finished article. Here you can see that the 8 bolt holes that will secure the liner have been drilled, together with the hornguide face. The end stop at the top of the hornguide has also been machined to the right dimension from the base of the frame. | |

| Preparing for Final Assembly of Frames | |

| 28/09/2020 | |

|

|

| When the frames return to the assembly shop we will be attaching the frame extensions together with the dragbox. Initially the frames lay across the shop but, with the frame extensions in place, the frames will be too long. So frames will be aligned pointing down the shop. All of our components have now been reorganised in preparation. In the photo, you can see front buffer beam, hind beam and rubbing plates, frame extensions, a box of plates including some running board plates, a pair of buffers, a motion bracket, sandboxes and the dragbox. | |

| Welding of Tender Lifting Brackets | |

| 28/09/2020 | |

|

|

| Last week we reported that the tender lifting brackets needed some welding. Here is Ian from CTL Seal in action doing the job. | |