Build Diary entries for August 2022

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Previous Month | Return to 2022 | Next Month |

| Cannon axle inspection. | |

| 02/08/2022 | |

| Our first cannon axle has come off the Jurrista machine centre at CTL Seal and is on the inspection table. The roller bearing goes inside the 10'' bore which is machined to an accuracy of +/_ .001'' CTL's Paul Parker has just measured the axlebox with a Faro Arm, which is a portable Coordinate Measureing Machine. We will get a full set of dimensional records as part of the Manufacturing Record Book. This is not the final inspection as the axleboxes will be going onto another machine for finaishing and then they will be inspected again. |

|

| Bogie parts (1) | |

| 08/08/2022 | |

|

|

| A busy day today. First job was to get the bogie wheels moved from the machine shop to the assembly shop. The wheels had been machined for oil release grooves. This is a feature of the modern railway (although it was dicussed in the 1950's British Railways Meetings) where high pressure oil is injected into the seat between the wheel and the axle and helps to remove the wheel from the axles without causing damage. Next job was fro Mike Healey to remove the sharp edge on he inner boss. The drawings call for a 1/32" radius here. | |

| Bogie parts (2) | |

| 08/08/2022 | |

|

|

| Next, Bob Ife and Ashly Shimwell got to work degreasing and getting some paint onto the wheels. This is an etch primer to be followed by coats of undercoat and top coat. We will leave this side of the wheels in primer but the boss on the inside face will be top coated as it will be virtually inaccessible once the wheel is joined to the axle and cannon box. The cannon boxes are on their last machining process and should have finished machining tomorrow (Aug 9) | |

| Bogie parts (3) | |

| 08/08/2022 | |

|

|

| While the painting was in progress, we wanted a trial fitting of the bogie side frame plates to the stretcher. In order to get gravity on our side, the bogie stretcher was turned upside down. Here Anthonly Pilkington is in charge of the overhead crane as we slowly to the stretcher over. Keith, Alan and Mike look on | |

| Bogie parts (4) | |

| 08/08/2022 | |

|

|

| With the bogie stretcher sitting on a pair of heavy duty trestles, it was time to lift the frame plates into position. The machined top of the frameplates has to sit tight up against a machined surface on the stretcher. With the stretcher upside down, gravity ensured that the frame plates were tight up against the stretcher. We also fitted the circular frame stays at the front and rear ends of the frame plates. After the photo was taken, the AWS receiver stay was also fitted. Everything is secured at this stage with temporary bolts. Next week, we will double check that everything is aligned correctly before proceeding to fit the permanent fitted bolts | |

| Tender 3D Model | |

| 14/08/2022 | |

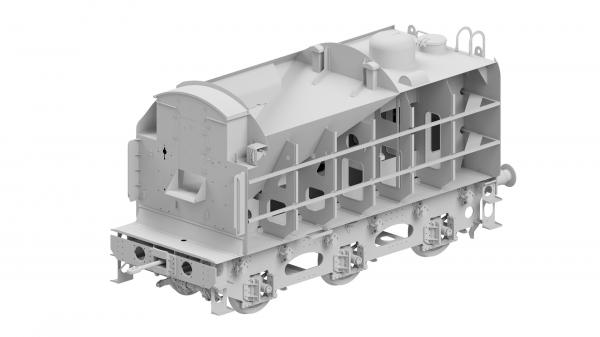

|

|

| James from our engineering team has been continuing work on the 3D model for the BR1F tender. This picture shows that parts you don't normally see, namely the internal stiffening plates within the water space. Once we see the potential size of the European Train Control System kit that we need to fit, we may have to change the size of the cupboards, possibly extending backwards | |

| Bogie Wheels | |

| 17/08/2022 | |

|

|

| We are currently getting everything ready so that we can send a kit of bits down to South Devon Railway Engineering in Buckfastleigh. They will assemble the complete bogie wheelset, i.e. axles, cannon boxes, wheels and tyres. Ashley has been beavering away this week getting the wheels painted. The inside faces of the wheels are not load bearing as we have roller bearing axleboxes. Therefore, we need to get some gloss paint on these faces as they will be hard to get at once the wheelset is assembled. | |

| Trailing Spring Hangers | |

| 22/08/2022 | |

|

|

| The trailing spring hangers are now in place fitted with temporary bolts. CTL Seal will now start to drill and ream the 8 holes per hanger to fix them to the firebox support stretcher. This will require drilling through from underneath. | |

| Bogie Cannon Axleboxes (1) | |

| 22/08/2022 | |

|

|

| Now that machining of the cannon boxes is complete, we can get a coat of primer paint on to provide some protection. Ashley, Keith and Alan get cracking with the degreaser to prepare the surfaces for painting. meanwhile Geoff measured the holes for the spring cups. These cups will fit in the recess marked B2. The pivot pins in the end of the spring cradles will sit in these cups. | |

| Bogie Cannon Axleboxes (2) | |

| 22/08/2022 | |

|

|

| Job done! Now to tackle the other one. | |

| Drain Plugs | |

| 22/08/2022 | |

|

|

| We've had the drain plugs manufactured by Generic Engineering in Rotherham. These drain plugs are from drawing SL/DE/21978 and are a modification introduced in April 1954. We believe that the rectangular slot in the threaded portion are to allow a sample to be taken for testing. If you've ever drained the oil from the sump of your classic car and not managed to get the oil up your sleeve, you will probable see how these could be of benefit! The 2 plugs on the stand still have the protection sleeve on the threads. |

|

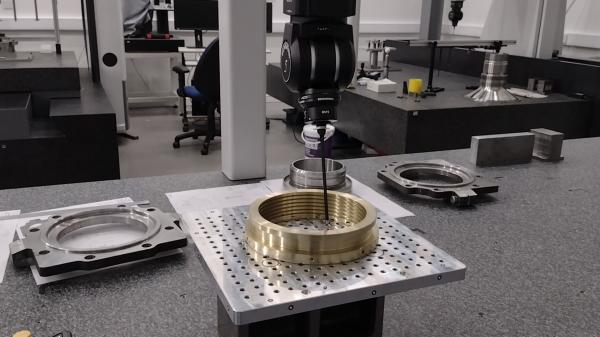

| Cannon Box Components | |

| 23/08/2022 | |

|

|

| In March, we placed an order for £21,000 order for 100 parts for the bogie cannon axle boxes, with Rotherham based Generic Engineering http://www.genericeng.co.uk. All were CNC machined and some parts are in halfves and need to be circular when joined together. Generic developed a method to do this. We did an intermediate inspection in June before the order was complete; Generic then did their first off inspection and now we are doing overchecks, as we do not want to have a problem when the axle boxes are assembled at the South Devon Railway. As part of our overchecks, we took one set of the critical components to Sheffield University’s Advanced Manufacturing Centre and had some key dimensions checked on their Co-ordinate Measuring Machine. The advantage of the Co-ordinate Measuring Machine is that operator feel or touch is eliminated with the machines touch-trigger probe and the probe can reach places that are difficult to get to with a micrometer. There is also consistency with measurement, and they can check diameter as well as circularity. The checks have gone well and have shown that we need to do a final adjustment to a spigot on the end cover, to give a good fit. The ultimate test will be to build up each axlebox, including a trial fit of the bearing in the axlebox. In the photo, the Enclosure Ring (in halves) is being measured. On the left is the axlebox end cover, again in halves. Behind the Enclosure Ring is the Enclosure Ring and Flinger. |

|