Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Bogie Frame Plate Fasteners |

| 09/05/2023 |

| |

|

| |

Today we were able to complete the first phase of installing bolts to fasten the frame plates to the central stretcher. In the photo, the bogie frame assembly is upside down. Where you can see nuts on the outside of the frame plates, there are temporary fasteners using standard hex bolts. 4 fitted, heavy drive hexagonal head bolts are installed on the bottom row and you can see Bob driving in the last bolt assisted by Mike tightening up the Philidas nut. Bob is using a copper head mallet to avoid damaging the bolt head. In order to avoid fouling the bogie spring cradle which lies alongside the frame plates, the other 13 fasteners per side will have countersunk head bolts. The frame assembly now needs to go to the machine shop for the countersinks to be formed in the frame plates. Photo by Chris Jones |

| |

|

| Platform Support Brackets |

| 15/05/2023 |

| |

|

| |

These platform support brackets were received from Alpenbury Precision Engineering in Rotherham today. The brackets support the platform plate (or running plate) alongside the smokebox. They will be bolted to pads welded into the smokebox. Manufacture is a 3 stage process. First the bracket is cut out of flat plate. The bracket is over long so that when it goes to the firm that will bend them, they have sufficient metal to get a purchase on. At the bending firm, the plates are bent to the correct profile. The final job, at Alpenbury is to form the correct profile on the short section and drill the holes. The rectangular brackets are fitted at each end of the smokebox and support the join between 2 platform plates. The tapered bracket is in the middle of the smokebox and supports the middle of platform plate 2. |

| |

|

| Levelling the Frames |

| 15/05/2023 |

| |

|

| |

Before the Open Day in April, the frames were moved to their new position within CTL Seal's Assembly Shop. One outstanding job was to ensure that the frames were level in their new position. Today Anthony and Craig from CTL Seal got to work with the overhead cranes and packing pieces to level the frames. You can see the green laser level line running along the frames. |

| |

|

| Dragbox Construction |

| 20/05/2023 |

| |

|

| |

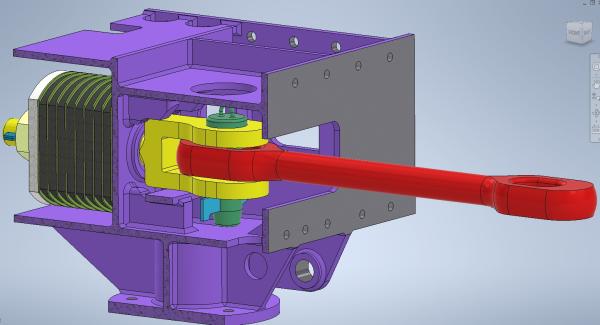

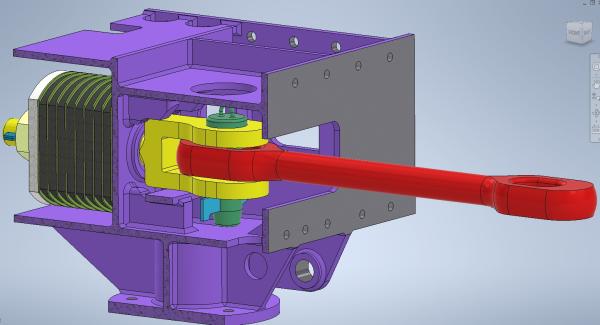

We have now placed an order on CTL Seal for the construction of the new dragbox. The story behind this design change can be found on the Construction > Design page of this web site. Keith has created a 3D model of the dragbox to check all of the dimensions. The front of the dragbox is to the left in the image with the drawbar extending to the tender on the right. On the left can been the Spencer Moulton drawbar spring which consists of a set of metal plates with rubber bonded onto the plates. |

| |

|

| New Dragbox into Production |

| 22/05/2023 |

| |

|

| |

A start has been made on our new dragbox at CTL Seal. These are the component plates which have cut to size. Most of the plates are the metric equivalent of 5/8 of an inch thick apart from the main back and side plates which need to be 3/4 of an inch thick after machining. Some round sections of plate are on order, these form an extension for the circular plate (seen in the photo) which the pony truck centring pin is fastened to. |

| |

|

| Bogie Spring Cradles |

| 22/05/2023 |

| |

|

| |

Meanwhile Ashley and Stephen got on with painting the bogie spring cradles. This will be a coat of paint a week job as 5 coats are required, 1 primer, 2 undercoat and 2 gloss. Once the coats have been applied we will turn the cradles the right way up so that Ashley can finish the job. |

| |

|

| Bogie Pivot Stretcher |

| 31/05/2023 |

| |

|

| |

We now need to fit the frame stretcher for the bogie pivot and the bogie bolsters in place. This requires 7 bolts per side, 5 of which are used by both the stretcher and the bolster. First we need to fit the 4 smaller bolts that fasten the stretcher to the frames, then the 5 bolts that secure the stretcher and the bolster to the frames. Unusually, the bolts have a cone head with the bolt head on the inside of the frames. Complicating the issue is that the bolt holes are very close to a horizontal weld. This means that the bolts were manufactured with a flat on one side so that the bolt head will sit tightly against the frame plate. The photo shows the location of the bolt (arrowed). Using a copper mallet to drive in the bolts is restricted as the smoke box saddle stretcher is immediately above. |

| |

|

| Bolt Insertion Tool |

| 31/05/2023 |

| |

|

| |

We had this tool made up to jack in the bolts for the bogie pivot frame stretcher. The threaded bar has a metric fine thread and the nuts bear on 2 cylindrical adaptors, the outer ends of which have a cone profile that engages with the head of the bolt. The castellated nut is being used as a spacer - it helps to avoid the adaptor turning. You can see the flats on both the bolts and the adaptor to clear the weld on the stretcher. |

| |

|