Mk 3 Dragbox Appeal

| If you would like to make a donation to the dragbox appeal, please click the button |

BR 2 Cylinder Pacific Locomotive Dragboxes

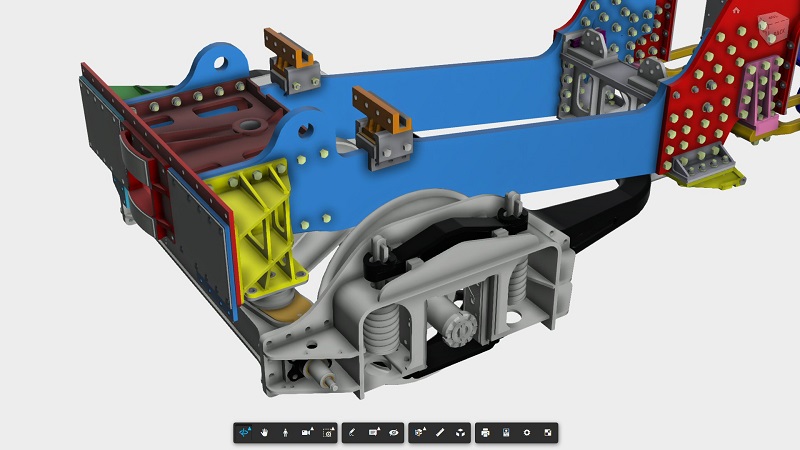

The dragbox is situated at the rear of the frame extensions and is the brown component you can see sitting between the 2 blue frame extensions (click image for a full size view). The vertical hole is where a large pin is located that engages with the locomotive/tender drawbar. This is what we refer to as the Mark 2 dragbox.

The Standard Steam Locomotive Company manufactured a dragbox in 2017 to the drawings we had available at the time. This is the dragbox having completed inspection.

Since then, a considerable amount of research has taken place at the National Railway Museum in York. We have managed to locate the minutes for the committees that we responsible for the initial design and subsequent developement of the BR Standard locomotives. The minutes run from 1950 to 1964 and contain a vast amount of useful information.

In 1957, the minutes tell us that problems were being experienced with "distorted" dragboxes and that the Swindon design office was tasked with developing a new design. In January 1959, the minutes recommend that the new design is fitted to all Class 7 (the Britannias) and Class 6 (Clans) locomotives. However, it was left to the regions to make the final decision as whether to implement or not. As this was the third design of dragbox to be fitted to the Clans, SSLC refer to this dragbox as the Mark 3 design.

SSLC have now established that the Mark 3 dragbox has actually been fitted to 70000 Britannia and 70013 Oliver Cromwell

The main difference in the dragboxes is that instead of having a solid drawbar between engine and tender in the Mark 2 design, the Mark 3 design has a drawbar spring (a set of large rubber circular pads) on the engine side of the drawbar. These bear on the front face plate of the dragbox. This is the Mark 3 design from our 3D CAD model.

If you would like to know more about the history of the dragbox development, please visit our dragbox design page.

Conclusion

As 72010 will need to operate on the modern higher speed railway (high speeds is when the problem with the Mk 2 dragbox emerged) and as a considerable number of customers will be paying for the premium dining experience, we have concluded that the project needs to adopt the Mark 3 dragbox design.