About Us

| Some of the Hengist Team meet Brell Ewart from the Princess Royal Class Locomotive Trust at CTL Seal in Sheffield |  |

Mission Statement

To administer the re-creation, operation and maintenance of a lost class of British steam locomotive, using original design drawings, but incorporating 21st century design and manufacturing techniques. The locomotive - BR Standard class 6, 'Clan' type, number 72010 and named "HENGIST", will be the next in line of the original BR production series, which had been cancelled in 1955 due to steel shortages and a national change of motive power policy.

The locomotive will be of a modern, go anywhere, low maintenance, low running cost design, perfect for the 21st century. It will complement and help to complete telling the story of the 12 classes of British Railways’ Standard Locomotive design.

To this effect we will facilitate its demonstration and provide a display for historical, educational and recreational purposes, both on the main line and on heritage railways throughout the country.

Standard Steam Locomotive Company Limited

British Railways built the first 10 Clan locomotives which were built in 1951 and 1952. BR did order a further 15 Clans under Crewe Works Order Lot 242, however, this order was subsequently cancelled. The Standard Steam Locomotive Company Limited (parent body of THE 'CLAN' PROJECT) has been set up to build the 11th "Clan", using the original British railways design drawings. The company is also a registered charity no 1062 320.

The company is a private company limited by guarantee and has no shareholders. The company is run entirely by volunteers with a Council of Management elected at the Annual General Meeting by the membership. The council meets every month to manage the project. A specialist engineering team forms the Engineering Committee.

The engine is being constructed as a continuation of the original British Railways design sequence, adopting all the improvements outlined in the Lot 242 order and taking the name & number of the next locomotive scheduled on the original 1954 Crewe works itinerary: 72010 "HENGIST". We also aim to tackle the fine tuning that was not completed in British Railways time.

In November 2017, the project entered a new and exciting phase. CTL Seal Co Ltd, based in Sheffield, have been contracted to start assembling the frames. The picture above shows members of the Council of Management and the Engineering Committee at CTL Seal's premises to view the start of the frame assembly.

Why Build a Clan?

A common question that we are asked is why we have decided to build a Clan 6MT pacific locomotive. The existing steam locomotive fleet as used on the main line and on heritage lines is now getting quite old. Maintenance costs are rising. A large number of these engines have spent a long time in the sea air at Woodhams scrapyard in Barry, South Wales. Although these locomotives can continue to be repaired, we believe that it is more cost effective to manufacture a new locomotive. This will ensure that steam locomotives can continue to fascinate for the foreseeable future.

So why pick the Clan as the locomotive? Cecil J. Allan, the doyen of train performance recording, said that the Clans were "One of the least distinguished in their performance of all the British standard locomotive types". Yet to crews who were prepared to adapt to them and to the operator, they were solid, reliable machines. We know that the draughting was not right - again Allan states "They can steam, providing they are worked fairly hard". We also know that the Standards did not employ modern draughting systems. 71000 Duke of Gloucester has shown what can be achieved if the draughting is improved and our aim is to provide an improved system for our locomotive.

The major reason for choosing a Clan is that it will provide a relatively modern, low maintenance, locomotive. It will have a go-anywhere capability as it has a higher route availability than other Pacific locomotives. A minor point is that we will fill a gap in locomotive history as none of the Clans were preserved.

Current Status - 2 October 2024

Click on the images for a larger image

Our base is at the premises of CTL Seal Ltd in NE Sheffield. CTL Seal are a specialist engineering company operating in various sectors including nuclear, oil & gas, sub-sea, mining and renewable energy. They are used to designing and building one-off projects and are admirably suited to working with the Clan Project. CTL Seal have been very generous in giving us an area in their assembly shop. This means that Hengist will be assembled in a nice dry and (relatively in winter!) warm area.

Establishing a base in Sheffield in November 2017 has allowed us to consolidate all of our components at a single base. With thanks to Canklow Storage we have obtained a large container which we have filled with components that have already been procured. Large frame components are stored within the assembly shop.

Frames

Most of our activity in 2018 was connected with the machining of the cast steel frame stretchers. These stretchers are unique to 71000 Duke Of Gloucester and the lot 242 Clans (see the history section). They hold the main frame plates apart and support the structure around the driving axles. The main frame assembly is shown below in the CTL Seal assembly area; note the original British Railways drawings on the boards in the background together with some drawings from our CAD models. 2019 saw the start of assembly of the frames - a lot of work has gone into ensuring that the frames are accurately aligned and that the frame stretchers are fitting closely.

The frames have been assembled with fitted bolts (which are a tight fit within the hole); here you can see Pete from CTL Seal reaming one of the holes using a magnetic base drill. Note that the frames are upside down in this image. The British Railways standard locomotive frames were assembled using cold riveting. That skill is very hard to find these days so we have used a fitted bolt solution. This provides a much stronger join at the expense of more work. Each frame hole is undersize and has been reamed out to the correct size. Philidas lock nuts have been used to secure the bolts.

In September 2020 the frames moved to the large Juaristi machining station within CTL Seal where the hornguides were machined. The rear frame extensions were not fitted at this stage as the assembly would be too large for the machining station. Here the axle box hornguides (The U shaped openings in the frame) were machined so that the hornguides across the frame are accurately aligned with each other. The frame keeps and keep pads were machined so that each keep will then be unique to its location. In October, the frames were returned to the assembly area. Here's a photo of the frames being set up on the Juaristi machining station.

The Covid lockdowns in 2020 and 2021 affected operations but we continued to make progress, albeit more slowly, throughout the pandemic.

A key activity in the late spring of 2021 was ensuring that the smokebox saddle was "fitted" to the inside of the frames. For this job, we brought in Dave Reynolds who is the Chief Mechanical Engineer at the East Lancashire Railway. This involved coating the sides of the smokebox saddle with engineering blue dye and then lowering the saddle back into position in the frames. Then the SSLC "Monday Gang" tightened up the 38 fixing bolts per side. Once that was complete, the 38 bolts were loosened and removed. The saddle was removed from the frames and Dave to see where the high points were on the frame by the transfer of engineers blue. A grinding wheel was used to remove the high spots and then the exercise was repeated - many times over 4 days! Here is Dave applying the engineers blue.

Over the summer of 2021, work involved fitting the frame extensions which sit under the firebox and have the engine dragbox at the rear. There are a lot of fastenings where the frame extensions are fastened to the main frames and these need to be carefully checked before machining the fitted to bolts to size. The photo shows the frame extensions being set up at the right height. The screw jacks are being used to set the height - relative to the bottom of the frames. Temporary sections of angle iron were tack welded to the top and bottom of the frame extensions to ensure the correct alignment.

Fixing the frame extensions means drilling and reaming all of the bolt holes to size and then driving in fitted bolts. First, the frame extensions will be fastened to the main frames; then the front firebox support stretcher will be fitted. This area will require the installation of 38 fitted bolts per side. Fitting work must ensure that the firebox support and the dragbox fit tightly within the frames. This work has been complex as each hole needs to be drilled and ream to produce a parallel circular hole, sometimes through 3 different plates. The hole is then measured accurately using a Bowers Gauge. A problem arose in 2022 in that we found that British Railways had designed a new dragbox for the Clans in the late nineteen fifties. After a considerable amount of internal debate we decided to scrap the existing dragbox and buid a new one to the latest design. This was manufactured in 2023 and was installed in the frames in 2024. We have acquired a Asquith "portable drill" which allows us to drill and ream the many fitted bolt holes. Here is it being used to drill the bolt holes in the hind beam gussets.

Once the gussets had been drilled/reamed, the Asquith was moved to the frames so that drilling/reaming of the frame extensions/dragbox could start. As of October 2024 we are part way through this process.

The bogie bolsters, which are fastened at the front of the frames and transfer the weight of the front of the engine to the bogie, had to be scrapped as we had no paperwork. New bolsters have been cast by Furniss and White and have been fitted to the frames.

In 2022, the front buffer beam wqas riveted in place. Riveting will also be required around the hind beam components.

Cylinder Pattern

Up in Scotland, our pattern maker - Tony Dance - is building the patterns for the main cylinders. This is a complex pattern consisting of 4 major sections. The 2 lower sections are 2 halves of the main driving cylinder. Sitting above that are the 2 halves of the valve cylinder. Tony will then have to build in all of the passages that transfer steam into the valve cylinder, from the valve cylinder to the driving cylinder and from the driving cylinder to the blastpipe. You can read all about the pattern making by following this link. Tony has completed the main motion cylinder pattern and is now working on the valve cylinder pattern. Although this is smaller in diameter than the motion cylinder, it is longer and has a more complex shape. There will be a lot of complex wood working required to create the "cores" and "prints" necessary to create the required holes in the finished casting. You can read about cores and prints by following this link. The current situation is that Tony is now building the valve cylinder core box which will make the air space within the cylinder. The main cylinder pattern and core box is basically complete. Now Tony needs to make the various loose pieces which provide bosses and attachment points for items like the cylinder drain cocks.

Bogie

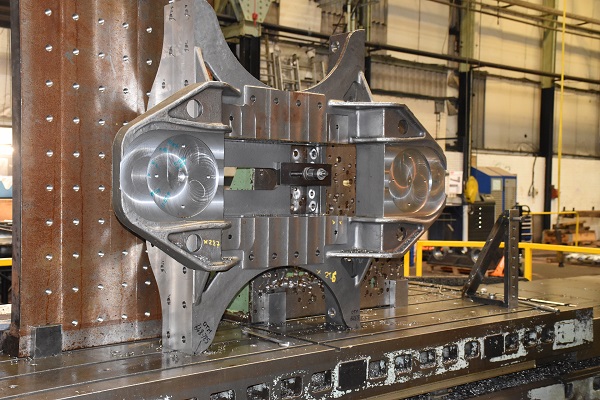

Most bogie components are now in stock. The image shows the central bogie stretcher casting on a machining station at CTL Seal. The bogie frame plates are attached to the sides of the stretcher - the vertical faces in the photo. The pivot on the locomotive frames engage with a centre slide which slides on the 2 central faces. You can see the circular recesses for the bolster pads. This is where the weight of the front of the engine is transferred to the bogie. Unfortunately the bogie frame plates were manufactured a long time ago and it has not been possible to locate the paperwork. In 2022, CTL Seal kindly procured a replacement set of plates.

The frame plates have been fitted to the bogie stretcher and checked for a tight fit. Temporary bolts have been used to tightly secure the frame plates to the central stretcher. The fore and aft frame stays have also been fitted. All bolt holes have been drilled and reamed to final size. Some of the bolts have countersunk heads which needed a deep countersink to be machined on the frame plate. This ensures that the bolt heads are flush in the frame and will not foul the bogie spring cradle.

Once the frame plates were firmly attached to the central bogie stretcher, we could start to fit the axlebox guides. Here Mike is reaming one of the holes in one of the axlebox guides.

Installing of axlebox guides needs a lot of attention. The axlebox guides require a steel liner to be bolted to the axlebox guide face, this has a manganese steel liner welded on. The manganese liner bears against the manganese liner on the cannon box and provides for a hard wearing surface. The key requirement is to ensure that we end up with the correct fine clearance between the 2 manganese liners. The liners are in stock and await the final fitting of a couple of axlebox guide bolts.Phase 2 of bogie construction involves the wheelsets. One of the main components is the cannon axlebox which is a casting comprising of 2 axleboxes and a central tube. This contains the wheel bearings and associated components; the axle runs through the centre. The first casting was rejected as cracks were found in key areas. An adjustment was made to the pattern and the cannon boxes were recast and machined. No detailed drawings were available for the other components for the cannon box. Detailed drawings have been produced by our design team and all of the parts have been manufactured, axle bearings have been procured from Timken. The wheelsets were assembled by South Devon Railway Engineering for assembly. Some minor jobs need completion, for example, the oil filler attachment.

Phase 3 of the bogie construction involves the suspension and side control springs. The 2 suspension springs have now been manufactured and are on site. The spring cradle plates are complete and are awaiting installation. We are continuing to explore options for the side control springs. The original design is for a rectangular section coil spring and it has been difficult to find a manufacturer with the capability to manufacture these.

Pony Truck

Next project will be the trailing or pony truck. This will be a coil spring system using the design from 71000 Duke of Gloucester which again was destined for the lot 242 Clans instead of the leaf spring design used on the original 10 Clans. You can see the CAD models in the Construction > Build Section. The pony truck wheels have been cast by Trefoil foundry in Sheffield. The frame keeps have been manufactured and other suspension parts on order.

Boiler

We have also started work on the boiler as this will be a long lead item. The image shows 70000 Britannia's boiler being installed at Crewe on 9 March 2010 - with thanks to the copyright owner Nigel Fraser Ker and his web site http://www.fraserker.com/britannia/ for allowing us to use this photo. Hengist's boiler is slightly smaller than 70000, we have most of the British Railways drawings for the boiler and firebox. Our first job is a design study to see where the existing design fits with modern boiler regulations. We are also examining where modern manufacturing techniques would be appropriate. We have been visiting potential suppliers as part of our design study. Our initial study has recommended that we build an all welded boiler with a steel inner firebox, using a working pressure of 250 psi (the original Clans had a working pressure of 225 psi).

Coupled Wheels

William Cook Cast Products Ltd have generously sponsored the manufacture of the 6 coupled wheels. SSLC worked with William Cook and were able to produce a 3D model of the coupled wheels. The 70013 Oliver Cromwell team were able to assist us in allowing Wiliam Cook and SSLC to laer scan 70013s coupled wheels. The 3D model produced was accurate enough to allow William Cook to produce the pattern using their CNC pattern manufacturing machine.

The 2 central driving wheels have been cast along with 2 of the 4 leading/trailing wheels.

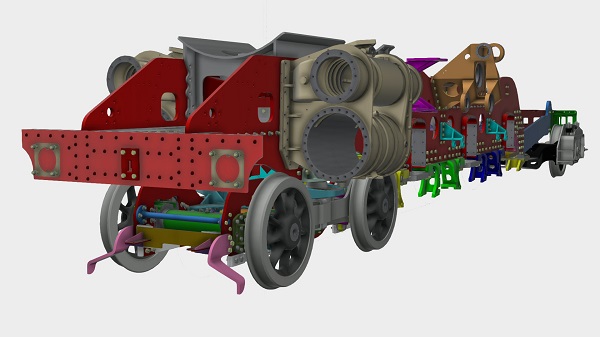

CAD Modelling

Click on the above image to enlarge it. One of the major advantages of building a locomotive in the 21st century is the availability of 3D computer modelling. As we develop each detailed drawing (from the original British Railways drawings), Keith then builds the drawing into our 3D model. This allows us to check that the drawing is correct as it fits into the model. The ability to manipulate the view of the model in 3D allows us to check for fit and any potential fouling problem.

Meet the Team

Council of Management

Members of the Council of Management are elected by the members and serve for a 3 year term.

Chairman |

Andrew England |

|

Andy is a dyslexic Yorkshireman who started his working life aged 16, as a welder in Rotherham. At the age of 30 he started an engineering company manufacturing items for the coal mining industry. Fast forward to present times, and Andy is now a shareholder and director of six companies employing over 230 people. The companies supply multiple industries and markets which include subsea, oil and gas, nuclear, new Biomass Plants, renewable, heavy construction from his companies located in Sheffield and Stoke. Andy is also involved in constructing and supplying components for ‘The Clan Project’s new build steam locomotive ~ Hengist. He also has a company that refurbishes train seats for the whole of the rail industry. At present, Andy is hoping to create 30 new jobs within the next 18 month period - fingers crossed with 50% through apprenticeships. |

Engineering Director |

Geoff Turner I Eng MIED |

|

Geoff has admired the BR Standard class of locomotives ever since his teenage years when he was railway modelling, seeing the style of the locos aesthetically pleasing, the range of classes following a family resemblance, with a class of locomotive for every duty. In his later years, as an engineering designer, only then fully appreciating Robin Riddles design philosophy in standardisation to produce the standard class locomotives. He never saw any 'Clans' when he was young; he was 12 years of age when steam finished on British Railways. So was a little envious when he discovered that his friend saw 72007, 72008 and 72009 when they were on Millhouses Shed, Sheffield. Millhouses Shed now demolished is not far from where he lives now. Geoff joined the Standard Steam Locomotive Company in 2002 after a visit to a gala event at Barrow Hill Roundhouse, near Chesterfield, where he saw the cab and front end. (Front Platform Plates, Cover Plates, Buffer Beam complete with oval buffers and Smokebox Door). He immediately struck a conversation with the team on the sales stall and was hooked. It's there he met Mike Sedgley who had organised the sales pitch for the project and Mike is still organising sales stands for the project today. A few years later when the project was based at Herston Works, Swanage he helped, on a couple of occasions, setting up supports for the Frame Extensions, for display, and drilling the Cab side plates. Geoff's previous involvement in heritage railways was with Peak Rail at Matlock and Buxton, in track laying, building work and involved on a number of committees. He also joined the team led by Brell Ewart to rescue 4MT 80080 from Barry scrap yard, going on to help with its strip down. A few years later, Geoff helped Phil Brown rescue 9F 92214. Geoff's career in engineering has taken him to Scotland, South Africa, Norway and Egypt, working in various industries. For the last 17 years he has worked in the oil and gas industry mainly designing subsea oil well equipment. When not involved with railways Geoff enjoys walking in the hills and valleys of Derbyshire with his wife and daughter, but not so much walking with his daughter these days as she is now living in Birmingham. |

Commercial Director |

Robert Ife ACIRO |

|

Bob has been interested in steam locomotives for most of his life, having witnessed the end of steam in the Nottingham area with the final ironstone workings in the hands of 8F locomotives. He became involved with steam preservation in the form of 9F 92212 when it was under restoration at the Great Central Railway, working on several aspects of both the engine and tender during this time. That was when he learned the meaning of heavy engineering. He joined the Clan Project in 2010 as an ordinary member, assisting on the sales stall when he was able at Loughborough. When the EGM was called in 2011, he volunteered to become part of the management team of the project, initially as member of the Council of Management without portfolio, assisting the other officers as required. He was later persuaded to take on the role of Commercial Officer, later Commercial Director, which he has fulfilled to the best of his ability since. He has since also taken over the Media portfolio, in addition to being the qualified company Health and Safety representative. Outside of the project, Bob is a professional train driver and, in this capacity, he can bring over 30 years of experience in the rail industry to the table for the benefit of the team as they make decisions about mainline running. Bob is now an Associate Member of the Institute of Rail Operators. This brings added benefits to the project, in having a qualified rail professional as part of the management team. |

BRSLOG Director |

Christopher Jones |

|

Chris has been an avid rail enthusiast all his life, being introduced to them by his father who had been a Fireman working out of 18D Staveley Midland, more widely known now as Barrow Hill Roundhouse. During the 1970's and 80's he travelled all over the country, especially Scotland behind the diesels using various rover tickets. His love of railways encompasses not only steam but also extends to modern freight, light railway networks, diesels, both heritage and modern plus model railways. He owns and regularly runs a 5in gauge 'Peak' diesel at his local Model Engineering Societies track and at other invited events around the country. His working life was spent entirely in the heavy engineering sector, specialising in parts and logistics, but also with a wide range of experience in forklift, crane and lifting operations. His many interests outside of railways includes, cycling, fell walking, photography, listening to rock music, including live bands, motorcycling, bird watching and nature in general. He has a passion for producing new build steam utilising the latest technology and using the highest spec materials. Chris is always kept busy with his HENGIST activities as he is a member of the engineering team, the management team, and also runs the sales events and co-ordinates the Monday working parties in addition to his British Rail Standard Locomotive Group duties. |

Project Director |

Ian Henderson CEng MBCS CITP |

|

Ian started his career as a pilot in the RAF. After gaining his wings, defence cuts meant a change of career, initially as an instructor at an Outward Bound establishment in the Lake District. The next stage in his career was to become a trials engineer testing conducting the early avionics trials for the Panavia Tornado aircraft. This involved 2 specially modified Blackburn Buccaneer aircraft, kitted out with Tornado avionics. Another job followed on the Tornado project, this time working as the company's engineering representative at BAe Warton (Preston) on the Tornado ADV Missile Management System. This involved supporting the equipment through initial ground rig trials through flight testing to production. After the conclusion of the development phase of the project, Ian changed jobs to a supplier to the NHS managing a large database system for a national NHS system. A key challenge, performed on time, on budget, was migrating 14 different regional Health Authority systems into a single national system. Shortly afterwards, Ian managed the transfer of the company into an employee owned organisation. Ian is a Chartered Engineer and is a Member of the British Computer Society. He is a paraglider pilot flying in the Lake District and is secretary of the local club. He has restored a number of old vehicles including an MGB and a Lightweight Land Rover. He still has the Triumph T90 motorcycle he bought at school! He has been interested in railways for as long as he can remember (and before according to his parents). |

Quality Director |

John Hind BSc CEng MIMechE |

|

John is a chartered mechanical engineer and member of the Institution of Mechanical Engineers, who has worked in management roles in manufacturing, quality, project management on large power station contracts for GEC/ALSTOM and automotive projects for Bentley Motors Ltd. The GEC/ALSTOM projects included nuclear, combined cycle, fossil-fired and hydropower plants in the UK and the Far East. Bentley projects included the iconic Continental GT, Arnage, and Mulsanne. In both industries, John worked on all project phases from starting with a blank sheet of paper through to completion. Project values were from £14M to £600M. John's experience runs from heavy engineering on power stations through to the intricacies of sewing patterns on car seats! As a toddler, John's first memory of steam is family trips from Kirkham to Blackpool South hauled by steam and the last days of the Stainmore Line. A family move to Somerset in the early 1960s meant John saw the last of Western Region steam and the transition to diesel. John's practical involvement with steam began in the early 70's when he was a member of the Taunton Group of the Great Western Society and as a 16-year-old spent summer weekends in 1970 and 1971 helping to rescue from the Barry scrapyard 5572 and 7202. 1971 saw a move to Manchester to start a student apprenticeship with GEC and a University course in mechanical engineering. In the early 1990s, John joined school friends from Taunton, as a shareholder in ex GWR 2-6-2 tank 5542 and was project engineer for the boiler overhaul and organised the manufacture of new parts for the boiler and locomotive. Since the return to traffic in 2002 he has helped with its maintenance. In 2003, John had two articles published in Steam Railway on new build steam. John was elected Chairman of the Advanced Steam Traction Trust in 2006 and for them designed the Lempor exhaust fitted to the KWVR's S160 No5820. Since taking voluntary redundancy from Bentley at the end of 2018, John volunteers in the workshops of the East Lancashire Railway and helped restore to running order, the 1881 built Lancashire and Yorkshire Railway 0-6-0 Saddletank No 752. John's other interests include cycling, skiing and Flight Simulation. |

Membership secretary |

James Spenceley |

|

James did not grow up in a railway family, however the family home was around the corner from a mainline railway station. So it was inevitable that with his brothers he spent his youth collecting numbers, travelling the network extensively and visiting sheds. Many nights were spent sleeping in compartments on overnight trains and in cold remote station waiting rooms. He often visited Barry scrap yard when it was in its ‘Glory Years’ full of those locomotives that had been laid to rest. On leaving school he completed his apprenticeship with the RAF (MOD) as a General Fitter/Welder on Ground Support Equipment. Uniquely being awarded Apprentice of the Year twice in a row. After a few years work the opportunity arose to convert to the airframe speciality and this led to working on the Tornado aircraft, amongst others. Upon leaving he then worked in the High Volume Air Conditioning (HVAC) industry, on both the manufacturing and installation sides. Redundancy allowed for a re-evaluation, so James decided to retrain and take time out to return to full time education as a mature student. A few years later having gained both a BEng(Hons) & MEng. This then provided the basis for moving south and spending a couple of decades at Cardiff University, School of Engineering, Manufacturing Engineering Centre. Involved with high value added engineering, rapid prototyping and technology transfer. Teaching & researching at a time when 3D printing was not the mainstream activity it is today. Away from work James has been an active rock climber, skier and alpinist. Climbing many routes and peaks. One memorable highlight was ascending Mont Blanc in the dark at night in quite extreme cold, in order to be sitting on the summit in silence at dawn, watching the sunrise over the Alps. Nowadays its more a case of walking and chasing the aurora borealis across northern Norway. |

Finance Manager |

Peter Lawne ACA, CIOT |

|

|

Other Posts

Secretary |

Stephen Loeber MIES AIRO |

|

I worked in the railway industry for 37 years, mainly within the signalling grades, however I was a trainer for five years doing signalling courses: I have now retired. I have been a member of the 73082 Camelot Locomotive Society for 23 years, being elected to the Committee of Management in the position of Secretary in 2002. I have been covering the role for 17 years. My main responsibility is arranging the AGM and general administrative duties. I have also been involved in changing the Society to a CIO. I have been a member of the Steam Tug Portwey Trust Ltd for 6 years, being elected onto the Management Committee in the position of Assistant Health & Safety Officer in 2016, then becoming the Health & Safety Officer, with my main responsibility being the managing of Health & Safety matters. I have been doing the role for 4 years, also become Company Administrator this year dealing with Companies House and Charities Commission, plus arranging AGM and general administrative duties. Also I have been a signalman with the Bluebell Railway for the past 3 years and have recently re-joined the South Devon Railway signalling department. In regards to Portwey I have been a stoker for the past 6 years now in training to be an engineer this is with assistance from the Boiler, Engineering Skills Training Trust. I am a member of the Institution of Engineers & Shipbuilders of Scotland and an affiliated member of the Institution of Railway Operators. |

Engineering Committee

Engineering Director |

Geoff Turner I Eng MIED |

|

Geoff has admired the BR Standard class of locomotives ever since his teenage years when he was railway modelling, seeing the style of the locos aesthetically pleasing, the range of classes following a family resemblance, with a class of locomotive for every duty. In his later years, as an engineering designer, only then fully appreciating Robin Riddles design philosophy in standardisation to produce the standard class locomotives. He never saw any 'Clans' when he was young; he was 12 years of age when steam finished on British Railways. So was a little envious when he discovered that his friend saw 72007, 72008 and 72009 when they were on Millhouses Shed, Sheffield. Millhouses Shed now demolished is not far from where he lives now. Geoff joined the Standard Steam Locomotive Company in 2002 after a visit to a gala event at Barrow Hill Roundhouse, near Chesterfield, where he saw the cab and front end. (Front Platform Plates, Cover Plates, Buffer Beam complete with oval buffers and Smokebox Door). He immediately struck a conversation with the team on the sales stall and was hooked. It's there he met Mike Sedgley who had organised the sales pitch for the project and Mike is still organising sales stands for the project today. A few years later when the project was based at Herston Works, Swanage he helped, on a couple of occasions, setting up supports for the Frame Extensions, for display, and drilling the Cab side plates. Geoff's previous involvement in heritage railways was with Peak Rail at Matlock and Buxton, in track laying, building work and involved on a number of committees. He also joined the team led by Brell Ewart to rescue 4MT 80080 from Barry scrap yard, going on to help with its strip down. A few years later, Geoff helped Phil Brown rescue 9F 92214. Geoff's career in engineering has taken him to Scotland, South Africa, Norway and Egypt, working in various industries. For the last 17 years he has worked in the oil and gas industry mainly designing subsea oil well equipment. When not involved with railways Geoff enjoys walking in the hills and valleys of Derbyshire with his wife and daughter, but not so much walking with his daughter these days as she is now living in Birmingham. |

James Conway MIED - CAD Modeller |

|

|

|

Keith Greenhow - CAD Modelling Manager |

|

|

I joined the Clan Project and Engineering Committee in 2014, after being persuaded by Geoff who I was working with at the time in subsea engineering, I was made responsible for CAD modelling. Although not a lifelong enthusiast, like others on the project, I have always found the engineering involved in all transport really interesting to me as an engineer and the offer of joining the project team building a full size steam loco was not to be missed and has fitted in nicely with my retirement. I've earned my crust in engineering since 1970 where I did a proper apprenticeship at David Brown Tractors, Meltham, studying at Huddersfield tech and Polytechnic which is now the university. When tractors closed down, at the end of the 80s, I went into contract mechanical design work mainly in the automotive industry but also aerospace, coal industry, sub-micron measuring and subsea oil and gas. Up to the early 90s this was all drawing board work but by then Personal Computers were becoming more affordable so I bought one and went back to Huddersfield tech to learn how to use it for 2D CAD. Of course things don't stand still so I learned 3D CAD whilst working in the subsea oil and gas industry which I use today for our Hengist locomotive. |

Ian Henderson C Eng, MBCS, CITP - Project Director |

|

|

Ian started his career as a pilot in the RAF. After gaining his wings, defence cuts meant a change of career, initially as an instructor at an Outward Bound establishment in the Lake District. The next stage in his career was to become a trials engineer testing conducting the early avionics trials for the Panavia Tornado aircraft. This involved 2 specially modified Blackburn Buccaneer aircraft, kitted out with Tornado avionics. Another job followed on the Tornado project, this time working as the company's engineering representative at BAe Warton (Preston) on the Tornado ADV Missile Management System. This involved supporting the equipment through initial ground rig trials through flight testing to production. After the conclusion of the project, Ian moved into a private company managing a large, mission critical database system for a national NHS system. A key challenge, performed on time, on budget, was migrating 14 different regional Health Authority systems into a single national system. Ian is a Chartered Engineer and is a Member of the British Computer Society. He is a paraglider pilot flying in the Lake District. He has restored a number of old vehicles including an MGB and a Lightweight Land Rover. He still has the Triumph T90 motorcycle he bought at school! He has been interested in railways for as long as he can remember (and before according to his parents). |

John Hind - Lead Engineer - Main Line Certification |

|

|

John is a chartered mechanical engineer and member of the Institution of Mechanical Engineers, who has worked in management roles in manufacturing, quality, project management on large power station contracts for GEC/ALSTOM and automotive projects for Bentley Motors Ltd. The GEC/ALSTOM projects included nuclear, combined cycle, fossil-fired and hydropower plants in the UK and the Far East. Bentley projects included the iconic Continental GT, Arnage, and Mulsanne. In both industries, John worked on all project phases from starting with a blank sheet of paper through to completion. Project values were from £14M to £600M. John's experience runs from heavy engineering on power stations through to the intricacies of sewing patterns on car seats! As a toddler, John's first memory of steam is family trips from Kirkham to Blackpool South hauled by steam and the last days of the Stainmore Line. A family move to Somerset in the early 1960s meant John saw the last of Western Region steam and the transition to diesel. John's practical involvement with steam began in the early 70's when he was a member of the Taunton Group of the Great Western Society and as a 16-year-old spent summer weekends in 1970 and 1971 helping to rescue from the Barry scrapyard 5572 and 7202. 1971 saw a move to Manchester to start a student apprenticeship with GEC and a University course in mechanical engineering. In the early 1990s, John joined school friends from Taunton, as a shareholder in ex GWR 2-6-2 tank 5542 and was project engineer for the boiler overhaul and organised the manufacture of new parts for the boiler and locomotive. Since the return to traffic in 2002 he has helped with its maintenance. In 2003, John had two articles published in Steam Railway on new build steam. John was elected Chairman of the Advanced Steam Traction Trust in 2006 and for them designed the Lempor exhaust fitted to the KWVR's S160 No5820. Since taking voluntary redundancy from Bentley at the end of 2018, John volunteers in the workshops of the East Lancashire Railway and helped restore to running order, the 1881 built Lancashire and Yorkshire Railway 0-6-0 Saddletank No 752. John's other interests include cycling, skiing and Flight Simulation. |

Chris Jones - BR Standard Locomotive Owners Group Contact |

|

|

Chris has been an avid rail enthusiast all his life, being introduced to them by his father who had been a Fireman working out of 18D Staveley Midland, more widely known now as Barrow Hill Roundhouse. During the 1970's and 80's he travelled all over the country, especially Scotland behind the diesels using various rover tickets. His love of railways encompasses not only steam but also extends to modern freight, light railway networks, diesels, both heritage and modern plus model railways. He owns and regularly runs a 5in gauge 'Peak' diesel at his local Model Engineering Societies track and at other invited events around the country. His working life was spent entirely in the heavy engineering sector, specialising in parts and logistics, but also with a wide range of experience in forklift, crane and lifting operations. His many interests outside of railways includes, cycling, fell walking, photography, listening to rock music, including live bands, motorcycling, bird watching and nature in general. He has a passion for producing new build steam utilising the latest technology and using the highest spec materials. Chris is always kept busy with his HENGIST activities as he is a member of the engineering team, the management team, and also runs the sales events and co-ordinates the Monday working parties in addition to his British Rail Standard Locomotive Group duties. |

Dr Phil Yates CEng MIMechE - Metrology Engineer |

|

|

Before attending University Phil was working as a time server vehicle technician. After completing his PhD on the study of diesel engine emissions, Phil started as a director in a small IT company working in the high volume printing industry. After 6 years of being constantly on call and spending more hours in the car than working on projects at home Phil joined the Advanced Manufacturing Research Centre (AMRC) in Sheffield. Working at the AMRC Phil works on industrial robots, industrial automation systems and large volume metrology. He has also worked on projects for many blue chip companies such as Airbus, BAE, Boeing, Rolls Royce, Jaguar Land Rover and Aston Martin. While at the AMRC Phil has submitted a patent application on a novel component of an autonomous mobile aircraft inspection system. Phil does not know much about railways at all, but likes the engineering challenge of building a steam locomotive from 2D drawings when all of the tacit knowledge has been lost. Phil is a Chartered Engineer and a member of the IMechE. Like other members of the engineering team Phil has worked on many types of vintage transport from F type Jaguars, Austin Nippy sports to a 1898 Humber keel. At present Phil has a fleet of Peugeot 205s with an average odometer reading of 250,000 miles and two Triumph motorcycles that he has owned since he was in his early 20s. |

|

Will Richardson - CAD Modeller |

Consultants

Consultant Metallurgist |

Nigel Hainsworth FIDiagE, PEng, IngPEur, IncMWeldI |

|

Nigel worked for 44 years at the British Steel Works, Scunthorpe, latterly Tata Steel. He spent his whole career in the Metallurgical Research Department / Metallurgical Laboratories starting off as an Apprentice Metallurgist and ultimately becoming Manager, Engineering Metallurgy. In this role he managed a Team of Specialist Metallurgists responsible for Material Selection, Welding, Investigation into Major Plant Incidents and Component Failures, NDE and Corrosion related issues. He also acted as the Metallurgical Consultant on Major Plant Enhancement Projects. He played an active role in the Quality of Purchased Plant Components, from Material Specification and, as a qualified Auditor, the Quality Auditing of Suppliers. This involved visits to Suppliers both in the UK and Europe to witness the various stages of Manufacture as agreed in their Quality Plans. This often included a Final Witness Inspection prior to Dispatch. As the Works had many miles of Rail Track and their own fleet of Locomotives with Rolling Stock, numerous investigations were conducted into failures of Rails, Sleepers, Pandrol Clips, Locomotive and Ore Wagon Springs, Axles and Wheels etc. Routine NDE of critical items was carried out as an essential part of the Fleet Inspection Plans. The latter and being a 1950/60’s ‘Train Spotter’ meant that Railways always were of a special interest and, on meeting up with a previous Work Colleague involved with Locomotive New Builds and Rebuilds was invited to a meeting of the Team building 72010 Hengist. This resulted in being accepted as Consultant Metallurgist on The Project. |