Tender

| Back to Index |

For most of the photos on this page, you can click the image for a larger picture.

The BR standard engines use 3 main types of tender, namely BR1, BR2 and BR3. The largest tenders were the BR1 series and there were a number of permutations within that series.

This is the BR1E(2) tender that was fitted to 71000 Duke of Gloucester. Note the high sides of the tender and the two sets of ladders. 71000 originally was fitted with a BR1E but this was replaced with a BR1J tender in 1957. The tender in the photo started off as a BR1C and was converted to a BR1E. Tender allocation on standards requires research!

The Clans were originally fitted with the BR1 tender. As you can see in the photo, the major difference is the inset coal bunker at the top of the tender. There is a small window at the front of the tender on each side so that the crew can look down the side of the tender when running backwards. However, it was rare in BR days to see a Pacific loco running backwards so the plan was to fit the lot 242 Clans with BR1B tenders which have high sides and do not have the inset bunker.

Here is a list of BR1 series tenders. Note that the fall plate is a hinged plate that connects the tender to the engine. The BR1 fitted locomotives had a cab floor that extends rearwards right under the tender front. This provided a firm platform for the fireman but came with the disadvantage of a draughty cab. This was dispensed with in later builds and a convential fall plate fitted

| Series | Water | Coal | Fitted to | Notes |

|---|---|---|---|---|

| BR1 | 4,250 gallons | 7 tons | 7MT, 6MT, 5MT | Inset Coal Bunker, no fall plate |

| BR1A | 5,000 gallons | 7 tons | 7MT - Originally coupled to 70025-9 | Inset Coal Bunker, no fall plate |

| BR1B | 4,725 gallons | 7 tons | 5MT, 4MT (both classes) | High sides. With fallplate |

| BR1C | 4,725 gallons | 9 tons | 5MT | High sides. With fallplate |

| BR1D | 4,725 gallons | 9 tons | 7MT - 70045-54 | High sides. With fallplate. Coal pusher |

| BR1E | 4,725 gallons | 10 tons | 8P, 9F (92150) | High sides and back. With fallplate |

| BR1F | 5,625 gallons | 7 tons | 5MT, 9F | High sides. With fallplate |

| BR1G | 5,000 gallons | 7 tons | 5MT, 9F | Inset Coal Bunker. With fallplate and gangway doors |

| BR1H | 4,250 gallons | 7 tons | 5MT | Inset Coal Bunker. With fallplate and gangway doors |

| BR1J | 4,325 gallons | 10 tons | 8P | High sides and valances. With fallplate and gangway doors. Coal pusher |

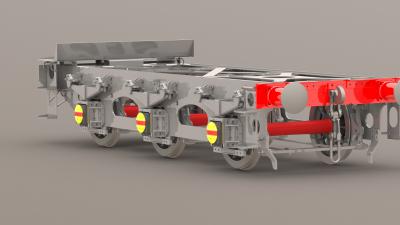

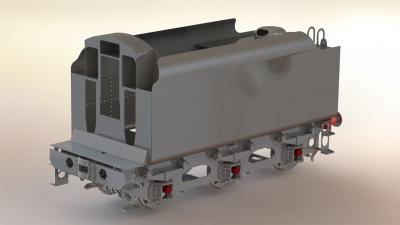

Hengist is being designed for the main line. Here the most important factor in any schedule is water. Our original plan was to fit a BR1B tender which would give us a larger water capacity than the original BR1 tender. However, other options are available (e.g. BR1F, BR1G) which would a greater water capacity. We have now decided that we will build a BR1F tender for Hengist. This will give 5,625 gallons of water and sufficient coal for any main line journey. Other issues that need design consideration include

- With the slow increase in the amount of electrification, a coal pusher could remove the need for the crew to go into the bunker to shovel coal forward. However this takes up valuable space for coal and water.

- A dome at the rear of the tender was originally provided as part of the water pickup system at water troughs. Although this could be removed entirely, it's likely that a cosmetic dome would be provided

- We will need to provide water hose connections at track level on both sides of the tender - again this removes the need to climb on the tender under electrification wires

- Electronics. Main line running requires a number of electronic systems (ERTMS, OTMR, TPWS). The tender may represent a slightly less hostile environment than the loco.

- The loco will need to have both air and vacuum braking, the former for main line running, the latter for heritage running. As a minimum, the tender will need air connections to the train