Build Diary entries for July 2023

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Previous Month | Return to 2023 | Next Month |

| Measuring Holes in Bogie Frames | |

| 03/07/2023 | |

|

|

| With the bogie frames back in the assembly shop we spent most of the day measuring the holes that will require countersink head bolts - this is to avoid a standard hexagon head bolt fouling the bogie spring cradle which lies alongside the frames. To measure the internal diameter we use a Bowers Gauge which is an internal micrometer. Before starting measuring, we ensured that the gauge was calibrated by using a 35mm calibration piece. All measurements are an offset from this 35mm, so the reading for the hole in the picture is 35mm - 9.59mm = 25.41mm or just over 1 inch. | |

| Cab Fittings | |

| 03/07/2023 | |

|

|

| Our cab has been sitting outdoors for a long time and we need to get it painted before the winter. Mike S led a group trying out some of the cab fittings that we have in stock. These are the damper or ashpan door controls. The original lot 221 Clans only had doors at the front of the ashpan which are opened and closed by the top handwheel. The lot 242 design for 72010 had an additional door at the rear of the ashpan which is controlled by the lower handwheel. We've identified that the eye at the end of the operating rod engages with a bell crank (or L lever). This is mounted on a bracket which will need a pad welding to the side plate of the cab. | |

| New Dragbox - Fabrication Starts | |

| 10/07/2023 | |

|

|

| Our new dragbox is now in the fabrication shop at CTL Seal. Here Tony from CTL Seal marks out the main bottom plate. Initially he will tack weld all of the plates together and make sure everything fits before starting the final welds. | |

| Dragbox | |

| 17/07/2023 | |

|

|

| Our new dragbox is taking shape at CTL Seal. The first parts have been tack welded together in preparation for doing the full welding. In the photo, the dragbox is upside down and the back plate is on the right. The semicircular plates and the circular plate are the bottom extension where the pony truck centring pin is attached. The pin engages in the back beam of the pony truck and spring gear within the back beam helps the engine enter and leave curved track. The plate with the small circular plate welded to it (and another one on the other side) are for attaching the safety links between engine and tender. Once the circular plates have been fully welded on, the resulting boss will be drilled through to allow the safety links to be attached. | |

| Bogie Bolster Bolts | |

| 17/07/2023 | |

|

|

| We're making slow progress with fitting the bolts for the bogie bolsters. The bolsters transfer the weight of the front of the engine to the bogie. The bolts to secure them pass through the bogie pivot stretcher, the main frames and the bolsters themselves - they also need to be a heavy drive (a tight fit). Unusually the bolts have cone heads (as in the original British Railways design) and the bolt head is on the inside, the nut being on the outside. We're using an Enerpac hydraulic jacking system to push the bolts into place. You can see one of the bolts that has been fitted on the left. The other hexagon head bolts are all temporary. | |

| Cab Work | |

| 17/07/2023 | |

|

|

| Meanwhile, out in the yard other members of the Monday gang have been working on the cab. On the right, we need to fit the feather edge beading that goes round the cab windows. The paint has been cleaned off in preparation for welding on the beading.On the left, the team are removing the temporary plate securing the roof to the cab sides. We have the brass top sliding window slides and they join the roof to the cab. This work is in preparation for drilling the holes in the slides. | |

| Axlebox Guides | |

| 17/07/2023 | |

|

|

| The 8 axlebox guides are now in the machine shop to have the final machining completed, Sam at CTL Seal has built this jig to hold them on the machine. The axlebox guide is just to right of the machine tool, with a dial gauge on the surface to be machined. Sam showed me that when moves the machine bed, the dial gauge did not move - so its ready to be machined. The axlebox guides will be machined to the dimensions on the British railways drawings. Once this is complete, the axlebox guides will be bolted to the bogie frames - again another job involving fitted bolts. CTL Seal have also received an order for the 8 axlebox liners. The liners are bolted to the axlebox guide; they have a manganese steel facing plate welded to the steel axlebox liner. Manganese steel is very hard wearing. The aim is to get a 0.010" to 0.017" clearance between the manganese steel facing plate on the axlebox liner and the manganese steel facing plate on the cannon axleboxes. |

|

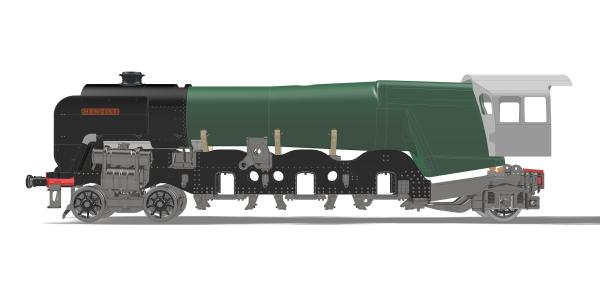

| Cab Modelling | |

| 30/07/2023 | |

|

|

| Our 3D modelling team are currently working on the cab. The cab for Hengist will be different from the original batch and is common with the last 10 Britannias built. It has a fall plate and the doors are fixed to the tender. You can read about the design issues regarding the cab by going to the Construction >> Design >> Cab section or by clicking on this link. | |