Build Diary entries for August 2023

Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Axlebox Guides Complete |

| 07/08/2023 |

| |

|

| |

The 8 axlebox guides have now completed machining so we picked them up from CTL Seal's inspection bay. |

| |

|

| Preparing for Axlebox Liners |

| 07/08/2023 |

| |

|

| |

Our next job with the axlebox liners will be to fit them to the bogie frames with yet another set of fitted bolts, 7 off per axle box guide. We will need to ensure that the axlebox guides are firmly up against the bogie frames. The upper bar in the photo is using a threaded bar as a jack. Ideally we need a pair so that the top and bottom faces are jacked. Once the axlebox guides are fully bolted, we will need to measure the distance between the faces. John is using an internal micrometer to measure the dimension as a trial. CTL Seal are currently manufacturing the axlebox liners that are bolted to these faces. This consist of a steel liner and a manganese steel face that will face a corresponding manganese steel face on the axle cannon boxes. The aim is to get a 0.010" to 0.017" clearance between the axlebox and the axlebox liners. |

| |

|

| Bogie Bolsters |

| 07/08/2023 |

| |

|

| |

The job of the bogie bolsters is to transmit the weight of the front of the locomotive to the bogie. The dome on the bottom of the bolster rests in a bolster cup that can "float" on a brass pad on the bogie stretcher. Fitting these bolsters has been a long job. The bolts are fitted bolts requiring a heavy drive to get them into the holes. The bolt heads are coned (rather than hexagonal) and are fitted from the inside. Consequently its very difficult to drive them in with a hammer. We've used a hydraulic jack for this job. To get a heavy drive bolt, the bolts have to be slightly oversize on the shank. If the shank is too big a diameter, then the bolt cannot be forced in. If the shank is too small a diameter then it will not provide the tight fit we need. So we specify the bolt shank to a tight tolerance. The other complication is that the bolt has to fit through 3 thicknesses of steel - the bogie pivot stretcher, the main frame and the bogie bolster. Today we achieved a milestone and all bolster bolts are fitted! |

| |

|

| Axlebox Guide Liners |

| 14/08/2023 |

| |

|

| |

A job in the machine shop at CTL Seal is the bogie axlebox guide liners. The liner consists of a steel plate machined in a shallow "U" shape. This will be bolted to the axlebox guide with the "U" facing the axlebox guide and seating on the sides of the guide. The inwards face will have manganese steel liners welded to the steel liner and then machined down to the correct width - 1/4 inch or 6.35mm. Manganese liners are required on the face and side of the steel liner, matching the manganese steel liners that have been welded to the cannon axleboxes. The photo shows the manganese steel liners prepared for the machine shop, the holes are for the cheese head bolts that retain the liner on the axlebox guide. The heads of the bolts will be recessed below the working surface. |

| |

|

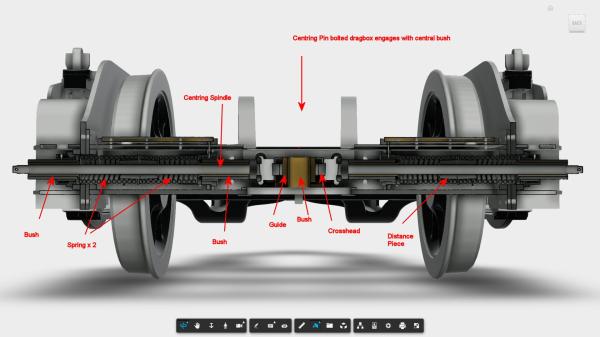

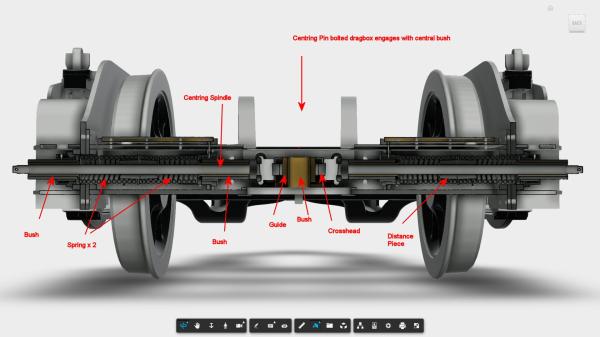

| Pony Truck - Design in Progress |

| 22/08/2023 |

| |

|

| |

Our design team is currently working on the pony truck, the 2 wheel truck behind the driving wheels. Its role is to carry the weight of the rear end of the locomotive. It also helps to stabilise the locomotive while running round a curve and also produces a smoother exit. The complicated part is the centring gear that is in the rear beam of the pony truck frame. A centring pin (currently on order) engages with a guide and crosshead through a slot in the top of the frame.The crosshead is free to move left and right but is restrained by 2 pairs of springs, 1 pair each side of the crosshead. The drawings for all these components is now in final developments and we aim to start placing orders soon. The springs should be straightforward to procure as they are round section coil springs as opposed to the bogie side control springs which are rectangular in section. You can out more about the pony truck by clicking this link. |

| |

|