Here are the diary entries for this month. You can use the forward and backward links to see the next or previous months. Most photos taken before 2018 are small size. From 2018 onwards, most photos you see below will have a link to a full size image by clicking on the photo.

| Pony Truck Pivot Pin |

| 05/02/2024 |

| |

|

| |

On Monday we collected the pony truck pivot pin from Alpenbury Engineering in Rotherham. The pony truck is a delta truck with the apex of the delta at the front where it pivots. This pin passes through a taper hole at the bottom of the main part of the stretcher, through the bush at the front of the pony truck radial arm and then through another taper hole in a support bracket bolted to the bottom of the firebox support stretcher. A nut secures the bottom of the pin retained by a cotter and split pin. Note that the central part of the pin that engages with cast iron bush in the pony truck radial arm is barrel shaped to allow for roll movements in the pony truck. The hole is for a grease lubrication feed. |

| |

|

| Brake Hanger Brackets |

| 06/02/2024 |

| |

|

| |

Mike H has had the spindle of our Asquith "portable" drill repaired so that it now runs true. The drill isn't that portable as it relies on us using the overhead crane to move it! On Monday we started the job of reaming the holes for the brake hanger brackets, 3 per side. Here, Geoff is using the telescopic internal gauge to check the dimensions of the holes after reaming. |

| |

|

| Brake Hanger Brackets Again |

| 12/02/2024 |

| |

|

| |

We couldn't do the middle left hand brake hanger bracket last week because Neil was polishing it up for display at the Doncaster Model Railway Show and our stand. So today it was back on the frames and Mike H got to work with the Asquith drill. We have to use a spindle extension as the yellow frame support stands prevent us getting any closer. In order to do the right hand side, we will need to get the frames moved to the left. |

| |

|

| Drain Plugs |

| 12/02/2024 |

| |

|

| |

Today we fitted these drain plugs to the bogie cannon axleboxes. As the drawing is dated April 1954 it must have been a modification to the original design. Note how the drain plug has a 45 degree slot. This allows an oil sample to be taken without removing the plug entirely. A copper washer is fitted between the drain plug and the body. The hole in the hexagon head is so that the plug can be wire locked in position. |

| |

|

| Spring End Shoes (1) |

| 19/02/2024 |

| |

|

| |

Today we took delivery of 24 spring end shoes from Tyler Bros Ltd in Sutton in Ashfield. These form part of the spring suspension system. We need 8 for the bogie, 12 for the driving wheels and 4 for the pony truck. The centre portion has been case hardened and they have been given an anti corrosion coating. The 8 for the bogie have been cleaned. See below for an expalanation of how they fit in the suspension system. |

| |

|

| Spring End Shoes (2) |

| 19/02/2024 |

| |

|

| |

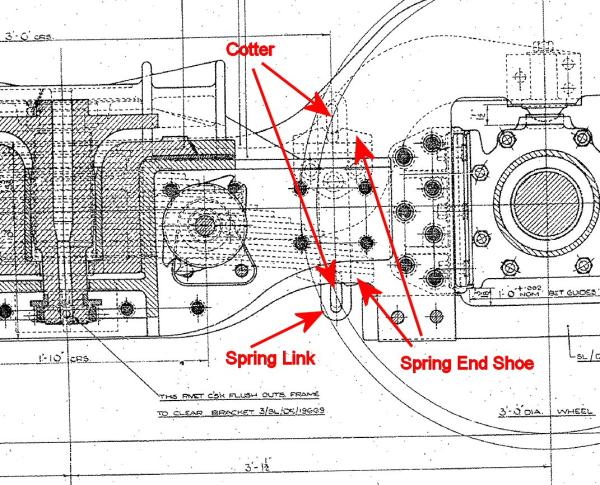

This is how the spring end shoes are used on the bogie. The upper spring end shoe sits in an oval slot in a bracket on the bogie spring cradle. A spring link passes through the centre of the spring end shoe - this has an oval slot in each end. A cotter passes through the oval slot and engages in the grooves in the spring end shoe. There are 13 different cotters, all different in height. The smallest one is 1-15/16 inches high and the largest one is 2-11/16 inches high. When the locomotive is finished. it will be necessary to weight it. The cotters are selected to give the correct weight distribution on the wheels. |

| |

|

| Spring End Shoes (3) |

| 19/02/2024 |

| |

|

| |

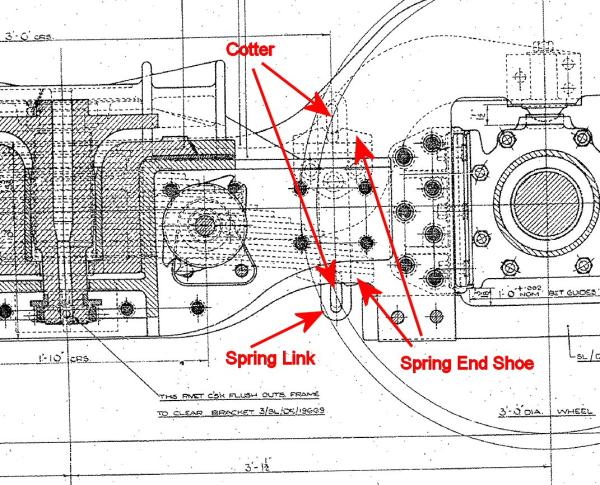

This is how the spring end shoes fit in the bogie spring cradle. |

| |

|

| Casting of Pony Truck Wheels |

| 26/02/2024 |

| |

|

| |

Today, our 2 pony truck wheels were cast at Trefoil Steel, Tinsley, Sheffield. In the photo, the 2 halves of the mould are being joined together prior to casting. Tomorrow, 27 February, the wheels will be broken out of the mould having cooled down overnight |

| |

|

| New Dragbox |

| 26/02/2024 |

| |

|

| |

This afternoon, the old dragbox was removed from the frames and the new dragbox installed. This is a trial fit as as we need to do some work to get it firmly butting up against the rear face of the frames. Anthony from CTL Seal is about to install the dragbox in the frames; in the photo. the rear face is facing the camera. |

| |

|

| New Dragbox (2) |

| 26/02/2024 |

| |

|

| |

Here's a view of the new dragbox temporarily in place. |

| |

|